How to Find Reliable Injection Molding Services in China

The important meeting has recently finished, your new product is a go, the schedule is tight, and funding is, to put it mildly, limited. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

You nod, of course. On paper, it’s logical. The cost savings can be huge. Yet your thoughts are already spinning. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

But here’s the catch. Procuring plastic mold company needn’t be a roll of the dice. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Ignore the nightmare anecdotes. Let’s walk through a real-world playbook for getting it right.

Step One: Do Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. It’s akin to asking someone to price-build “a structure” with no details. You’ll get wildly varied quotes that are useless.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. This becomes the bedrock of your sourcing project.

What belongs in your RFQ?

First, your 3D CAD files. These are non-negotiable. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the master blueprint for your part’s geometry.

But 3D isn’t enough. Add comprehensive 2D plans. Here you specify what 3D can’t show. Think tolerances, material grades, finish specs, and any feature-critical notes. Any seal surfaces or critical hole sizes must be clearly labeled.

After that, material choice. Don’t just say “Plastic.” Nor just “ABS.” Be explicit. Call out SABIC Cycolac MG38 (black), for example. Why be exact? Because there are thousands of plastic variations. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

Don’t forget the commercial info. What’s your forecasted annual volume (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. The tool design, the number of cavities, and the price per part all hinge on this number.

The Great Supplier Hunt

Okay, your RFQ package is a work of art. now, who do you send it to? Online sourcing is global but crowded. Locating vendors is easy; vetting them is the real challenge.

Your search will likely start on platforms like Alibaba or Made-in-China.com. These are great for casting a wide net and getting a feel for the landscape. But think of them as a starting point, not the finish line. Narrow your pool to about a dozen promising firms.

Still, you must dig deeper. Think about engaging a sourcing agent. True, they charge a fee. But a good one has a vetted network of factories they trust. They bridge language and cultural gaps. For a first-time project, this can be an invaluable safety net. Think of it as insurance for your project timeline.

Also consider trade fairs. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Meeting onsite is unbeatable. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. And don’t forget the oldest trick in the book: referrals. Tap your professional contacts. A recommendation from a trusted peer is often worth its weight in gold.

Shortlisting Serious Suppliers

After firing off that RFQ to a broad pool, bids begin to arrive. Some will be shockingly low, others surprisingly high. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How to proceed? It blends technical checks with intuition.

Begin with responsiveness. Is their turnaround swift and concise? Is their English good enough for complex technical discussions? But here’s the real test: Are they asking you intelligent questions? A great supplier will review your RFQ and come back with thoughts. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” That’s a huge positive sign. It shows they’re engaged and experienced. Anyone who simply agrees to all specs is a red flag.

Afterward, verify their technical arsenal. Get their tooling inventory. Seek samples or case studies of comparable projects. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Then comes the audit. You can’t skip this. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s a tiny cost for huge peace of mind.

From Digital File to Physical Part

You’ve selected your partner. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Now the real fun begins.

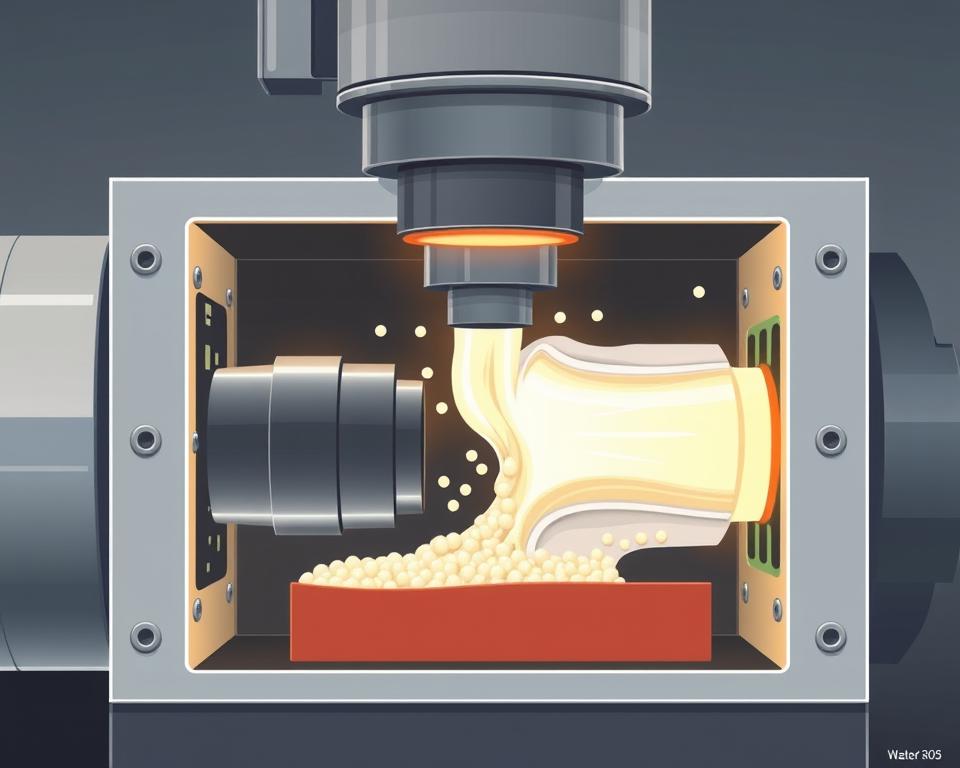

Initially, expect a DFM report. Design for Manufacturability (DFM) is essential. It’s their professional review of your CAD. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A detailed DFM shows expertise. It’s a collaboration. You iterate with their team to optimize the mold.

When you greenlight the DFM, they machine the mold. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are your initial mold shots. They are your moment of truth.

Be prepared: T1 samples are almost never perfect. That’s standard process. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold company samples. It could require several iterations. Build buffer time for sample iterations.

Eventually, you will receive a part that is perfect. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is now the benchmark sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Crossing the Finish Line

Receiving the golden sample seems like victory, but you’re not done. Now you’re entering the mass production phase. How do you maintain consistency for part 10,000?

Implement a robust QC plan. Often, you hire a pre-shipment inspection service. Use a third-party inspector again. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. They’ll send you a detailed report with photos and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This simple step prevents you from receiving a container full of scrap metal.

Finally, think about logistics. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, where you handle everything from their gate? These details have a big impact on your final landed cost.

China sourcing is a long-haul effort. It relies on partnership-building. See them as collaborators, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. It’s a challenging project, no doubt. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re set to succeed.